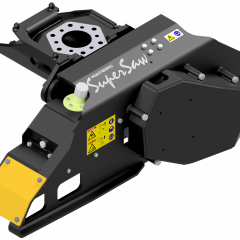

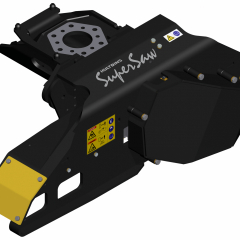

HULTDINS grapple saws: SuperSaw 650, 651

Grapple saws for large log diameters.

The SuperSaw 650 and 651 can be fitted with the particularly robust ¾″ bars and chains (11 mm material thickness). Bars up to 130 cm in length are therefore available. The smaller grapple saws can be fitted with .404″ pitch Harvester bars with up to 6.2 mm material thickness. The maximum bar length for practical purposes is limited by vibrations and the bar’s lateral deflection. In continuous operation, the .404″ pitch version can grapple saw through logs up to 75 cm in diameter; larger diameters require more-robust bars and preferably a more powerful motor. This is where SuperSaw 650 and 651 come in.

Both models are fitted with the HULTDINS SuperCut 300 “sawmill”. The rail feed, the chain oil supply, and a large grapple saw motor are all integrated in the one unit. An automatic chain tensioning is fitted as standard. You can choose either the 40 cc (200–265 l/min) or the 60 cc (265–300 l/min) grapple saw motor. The limitation of power is the maximum allowed power consumption of the 11H chain with 75 kW. These two models differ in their hydraulic control system: the SS 650 features a simpler return regulation, the 651 a pressure regulation. The SS 651 therefore attains the higher efficiency. A bar with 100 cm in length is fitted as standard. Rails up to 130 cm long are possible. The fitted chain is an Oregon 11H with a highly impressive service life and cutting performance.

The SuperSaw 650 and 651 casings are built very solidly and are suitable for excavator work. The mount is a HD version with 6 x M16 – 173 mm and 6 x M20 – 203 mm pitch circles. We recommend this grapple saw for excavators greater than 20 t. That the 6 x M20 – 203 pitch circle must be used for the INDEXATOR rotator GV124-S-203 then goes without saying.

The grapple saw can be used with the large SuperGrip I 520-S-VM and SuperGrip I 720-S-VM grapples.