INDEXATOR forestry rotators: XR series compact rotators for heavy work

INDEXATOR XR compact forestry rotators for fixed mount and dangle mount on handling machinery and excavators

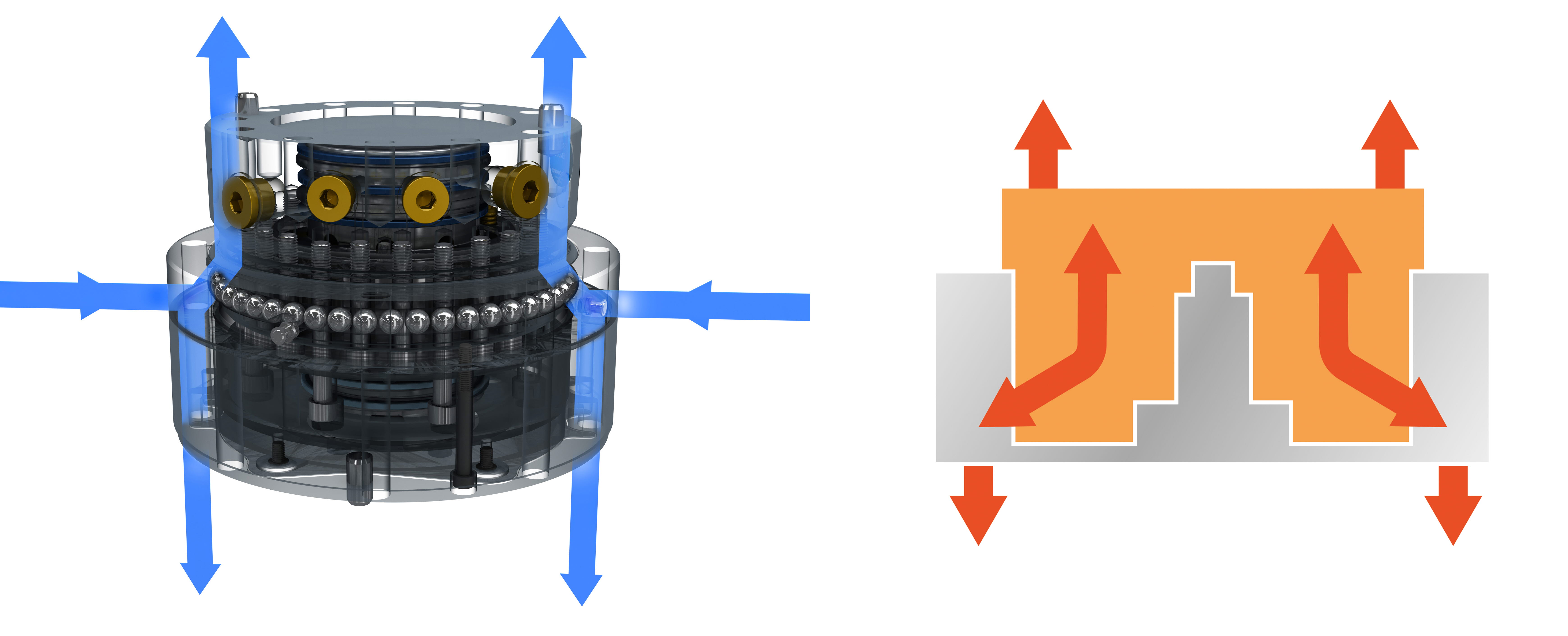

The INDEXATOR forestry rotators of the new XR series embody the experience gained from over forty years of forestry rotator manufacture and the latest findings in surface machining. At present, the series includes the XR-400 for 550 kN, the XR-500 for 700 kN, and the XR-600 for 850 kN maximum static load. The series is being expanded downwards on a continuous basis. The latest model is the XR-300 for 300 kN maximum static load. The INDEXATOR XR forestry rotators are extremely durable and can replace larger rotary mechanisms with ring gear. The large bearings transfer the radial and axial forces from the tool over the housing to the upper connection. The hydraulic drive operates independently of the bearing, and is therefore isolated from heavy shocks. Indexator XR forestry rotators have proved themselves under gruelling conditions, e.g. on dredgers; on scrap, timber, and natural stone handlers that work offshore and in sea water; and in many other fields. Indexator XR forestry rotators are characterised by their high torque and efficiency.

Thanks to the patented force and torque transfer system from Indexator, external forces can reach neither the motor nor the rotating union inside the XR forestry rotator. The forestry rotator’s service life is therefore longer than its rival products’.

Also the new INDEXATOR vane motor serves to extend the service life of XR forestry rotators. This vane motor safeguards a high torque, yet is insensitive to twisting. The new design featuring the slew base bearing, motor, and rotating union fitted as separate modules makes servicing and maintenance particularly easy and convenient. Indexator XR forestry rotators are long lived products – over the long term they are the most cost effective solution in their performance class.

The XR 300 is the smallest Indexator compact forestry rotator whose patented force and torque transfer system, wear resistant vane motor, generously dimensioned slew base bearing, and ease of maintenance cannot fail to convince every user. This finds testimony in the unanimous praise in the experience and opinion of customers who tested the prototype.