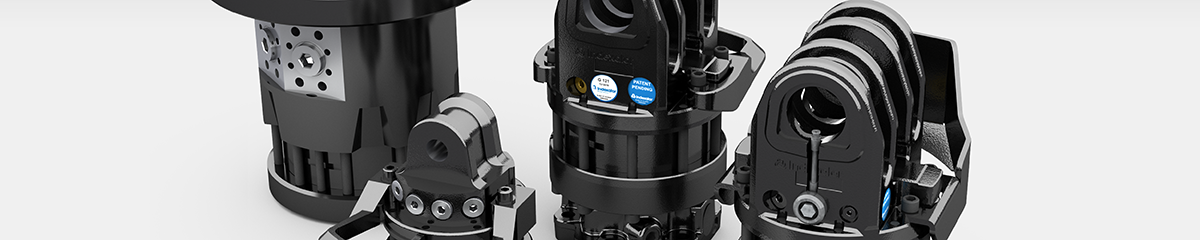

INDEXATOR forestry rotators for gruelling conditions

INDEXATOR – The leading manufacturer of forestry rotators for forest machinery and timber transport

Based in Vindeln in the north of Sweden, INDEXATOR AB has been linked closely to forest machinery since its founding. Today, INDEXATOR is the leading manufacturer of rotary motors for timber harvesting and transport worldwide. All major forest machinery manufacturers put their trust in INDEXATOR quality. The secret of the INDEXATOR forestry rotator’s long service life lies in the ultra precision machining of the running and sealing faces. All series have been designed for professional applications and are manufactured to very high quality standards. Indexator quality is appreciated by professionals.

Product properties of INDEXATOR forestry rotators:

- Highest material qualities

- Particularly long service life

- High cost effectiveness under gruelling conditions

Hydraulic forestry rotators, also known as rotary heads, rotary motors, or rotary servos, are designed to rotate and position precisely the attachments, e.g. grapples, pallet forks, load hooks, and harvester units, on a crane or excavator. They are the machine’s wrist, while the grapple assumes the function of its fingers. Rotary motors come in a wide range of designs and drive types.

Common drive types for hydraulic rotary motors:

- Radial piston motors

- Axial piston motors

- Gerotor motors

- Rotary vane motors

All INDEXATOR forestry rotators are rotary vane motors. They are characterised by their particularly long service life.

Attachment types

Cardanic suspension

The cardanic suspension is the most common attachment type for timber grapples. The forestry rotator is connected to the boom tip via a link with 2 bolts arranged at a right angle to each other to pivot on two axes in all directions at an angle of up to 45 degrees. The forestry rotator can swing freely under the forces acting on it and is loaded predominantly in the axial direction.

Rigid attachments

The rotary motor is attached rigidly to the boom tip, e.g. on the excavator’s bucket arm. For this purpose, the forestry rotator, e.g. the INDEXATOR XR, presents a set of (threaded) holes on its top side that can be used to bolt it to a plate, e.g. on a quick coppler. The bottom side of the forestry rotator also presents a set of holes to which the tools are bolted. The tool, however, moves with the excavator’s bucket cylinder, and so is subjected to high lateral forces. The forestry rotator, the boom tip, and the tools must be able to withstand these forces. It is the typical attachment used for sorting grapples on excavators.

Type and number of hydraulic swivels on forestry rotators

Hydraulic rotary motors feature at least two hydraulic connections for “Rotate ACW” and “Rotate CW”. In addition, “hydraulic lines” can be routed through the endlessly turning forestry rotator. The INDEXATOR forestry rotators of the AV and H series, designed for attachment to harvesters, feature connections for the rotary function only. The Indexator series GV, G, IR, XR present at least two other hydraulic swivels for the functions “Open grapple” and “Close grapple”. The INDEXATOR forestry rotator GV124 presents a total of four swivels, two for the grapple function and two e.g. for a grapple saw.

The right choice of forestry rotator for your application

The first important question is whether you are planning a cardanic suspension or a rigid attachment. The cardanic suspension is always lighter and cheaper. Next you must determine the highest load to be taken up. A forestry rotator’s specifications includes its maximum static and maximum dynamic load. Base your judgement on the maximum dynamic load. The forestry rotator can then lift, turn, and position this load in continuous operation. Work such as loading timber or scrap involves many fast load reversals, placing great demands on the crane and forestry rotator. Now choose the suitable mount at the top between the boom tip and forestry rotator, and the fittings at the bottom for taking the tool. Is there an adequate number of hydraulic swivels for your application?

We’ll be pleased to assist you in choosing the right swing link and forestry rotator – just call us!