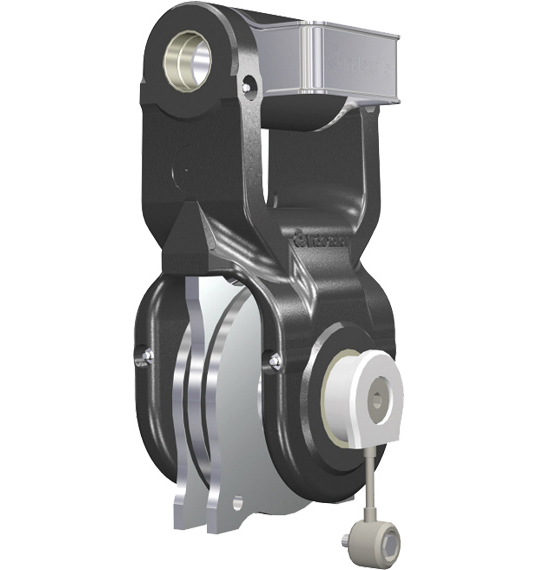

Swing-Rotator-Grapple for forwarders

The most important tool on a forwarder is the crane with timber grapple, which is decisive for the machine’s overall productivity.

When does a timber grapple match perfectly the forwarder?

1. Geometry: The claws must roll in the timber in an ordered fashion, at the same time aligning and bundling it as parallel as possible.

2. Speed and strength: The timber grapple must be able to seize specific, separate logs – short closing and opening times are important. Unloading productivity depends crucially on the high filling ratio and uniform rollout.

3. Durability: Owing to the many working hours of a forwarder, the durability of HULTDINS timber grapples is of particular advantage. The perfected design eliminates trouble with leaking cylinders and lost bolts, even after many working hours.

4. Elimination of skid damage: The must for a forwarder in thinning operation is a high performance, low maintenance swing brake. And the matching longlife G rotator – none are as good as INDEXATOR .

5. Frequent skidding of hardwood and thick long timber is best done with a reinforced timber grapple of the series S and a rotator delivering higher torque.

The combinations of swing joints, forestry rotator, and timber grapple we recommend for typical forwarders:

HULTDINS timber grapple SuperGrip I & II

- SuperGrip II 260, 300, 360 for 2–6 m softwood and cranes < 10 t

- SuperGrip II 260-S, 300-S, 360-S, 420-S for soft- and hardwood and powerful cranes < 20 t

- SuperGrip I 360-S-VM, 420-S-VM for thick soft- and hardwood and long timber for the most powerful forwarder cranes

- Optional moving piston rod cowl